Manual FlowFriend Standard and PRO

Translation, Übersetzung & Traduction:

Installation and User‘s Guide

FlowFriend® - Standard & Pro

FlowFriend is manufactured by and a registered trademark of Stiloh

Air-Aqua BV

Weth. Ohmannstraat 1

7951 SB Staphorst

The Netherlands

+31 (0)522 468963

info@air-aqua.com

Table of Contents

1. Foreword

2. Defects and claims for compensation, disclaimer

2.1 Defects and claims for compensation

2.2 Warranty and subsequal damage

2.3 Hidden defects

2.4 Improper application

2.5 Returning the product

2.6 Claims

2.7 Spare parts

2.8 Subject to alterations

3. General

3.1 Pump and drive description

3.2 Warning Notes

3.3 Use of the pump - Symbols used

4. Fields of application

5. Installation/Fitting

6. Operating the pump

6.1 Siting the pump

6.2 Inlet pipe (intake side)

6.3 Pressure pipe (Pump outlet/pressure side)

6.4 Electrical connection – setting-up operation

7. Maintenance and cleaning

7.1 Disassembling/turning the pump housing

7.2 Decalcification and cleaning of the impeller

8. User guide Keyboard

8.1 Run/Stop Mode

8.2 Keys “UP” and “DOWN”

8.3 Showing the current power consumption

8.4 Operations hour counter

8.5 Software Version

8.6 Power Module Temperature

8.7 Led Indicators

9. Optional 0-10V drive

10. Failure Mode Description

10.1 Overheating

10.2 Stalling

10.3 Communication error

10.4 Internal electrical failures

11. Technical Information

12. Distributor’s declaration

Thank you for purchasing a FlowFriend pump. This pump is a high quality product with the highest manufacturing demands.

This manual is intended to help you set up the pump for use and provide advice on the required maintenance procedures. This guide aims to provide you with correct and complete information.

To ensure long-lasting satisfaction with this product, please read this manual carefully and follow our guidelines.

If you are uncertain about the contents of this guide or do not fully understand the assembly instructions and/ or anything regarding this product, please contact the shop where the product was purchased.

This manual is intended to inform you correctly and comprehensively, i.e. also over potential risks caused by the pump. The user, fitter and maintenance technician is responsible for checking compliance

with the procedures and advice in this manual. This pump is built using state-of-the art technology and to ensure compliance with existing safety regulations. Nevertheless this device may cause risks for individuals and for property if it is used improperly or not according to its designated use or if safety advice is ignored.

If the pump is used improperly, the liability of the manufacturer and the operating permit are void.

For safety reasons, children and juveniles under the age of 16 and people who do not recognise the possible risks or who are not familiar with this manual may not use the device.

The combination of water and electricity can cause serious threat to life and limb when not installed according to the directions or when used improperly.

The General Terms and Conditions of Air-Aqua apply to all products.

2. Defects and claims for compensation, disclaimer

2.1 Defects and claims for compensation

Except in the case of a further claim, we are only liable for defects to the delivered goods until the risk has been transferred to

the purchaser. Minor deviations between the appearance and workmanship of the product delivered and the specifications in the contract

or minor limitations of usability will be deemed insignificant.

The warranted condition, endurance and usability of the product are solely subject to the specifications agreed in writing,

in the product specification and/or in this guide.

2.2 Warranty and subsequal damage

Our warranty for defects is strictly limited to supplementary performance. We will eliminate any defects or deliver substitute goods at our discretion.

Where supplementary performance fails or is disputed or impossible, the customer has the right to withdraw from the contract.

Air-Aqua and the manufacturer explicitly limit the warranty to the pump itself. We are not liable for any consequential damage or damage caused by a malfunction

or failure of the pump, such as loss of animals.

The customer is required to conduct a detailed inspection of the goods immediately after delivery. Any defects should be reported immediately in writing. Hidden defects should be reported immediately after their discovery.

The customer should report any damage caused during transport within 24 hours to the carrier and/or the delivery service. If the customer fails to meet the requirement to inspect the goods and report any defects or damage,

this will result in the loss of warranty.

We accept no liability for the improper application, use, maintenance or handling of the product by the customer or its subsidiaries, or for normal wear and tear.

This applies specifically to the consequences of thermal, chemical, electrochemical or electrical influences as well as for infringements of our use and maintenance guides.

The same applies to damage resulting from changes or adjustments made by the customer, which have not been approved by us beforehand.

In principle, the customer is responsible for damage directly attributed to the improper use of the product. If the customer returns the product, break-proof packaging should be used.

The customer is liable for any damage that can be attributed to inappropriate packaging.

Claims against us expire within a year after the initial delivery of the goods to the customer.

The same applies to damage claims, regardless of their legal cause. The limitation period does not apply to claims based on the malicious concealment of damage,

injury to life, body or health or any other damage resulting from intent or wanton negligence.

Our liability to deliver and stock spare parts is limited to the period of 5 years after initial shipment of the product. Our respective list prices apply to spare parts.

The manufacturer is entitled to change the product at any time without prior notice being required, as long as these changes improve the reliability or quality of the product.

No claims can be made if, for example, the design, functionality or performance of the pump fundamentally changes. The confirmed pump specifications are always guaranteed.

3.1 Pump and drive description

The synchronously driven, highly efficient, stainless steel pump FlowFriend ® consists of a permanent magnet motor, a complete electronic drive with an integrated power module (IPM)

and controller hardware and software with digital signal processor (DSP). The mains inputs are supplied with a power factor correction (PFC) and EMC filters. All drives comply with the

EN standards 61000-3-2 the EN 61000-2 and 61000-3 corresponding to the limit value class B according to EN 55011 for single and three phase devices.

Further verbal agreements, especially from preliminary talks, advertising and/or in related industrial standards, are only valid as an integral part of a written contract.

Only conditions and specifications specifically laid down by us are valid. We do not accept conditions or specifications laid down by third parties.

The specifications laid down in this guide are valid.

If the customer wishes to use the product for a purpose other than the intended purpose, he or she is obliged to

thoroughly explore the suitability of the product for this other purpose. We give no warranty and accept no liability for any use other than that explicitly approved by us in writing.

Any changes made to the product will result in the loss of warranty and all claims and rights will lapse.

The user is held responsible for the proper use of the pump. The user guide does not discharge you from your liability for the proper and safe application, installation,

operation and maintenance of the pump. On using this guide, you agree that in no circumstances can or will the manufacturer be held liable for any personal injuries or damage

to property that might result from using the device. This applies specifically to any damage caused by improper piping or plumbing. Damage due to failure to regularly clean or

maintain the pump is not covered by the warranty. This applies especially to calcinations and accumulated foreign particles such as sand or gravel, which can damage

rotors, bearings, rotor housing or motor housing that are not covered by warranty.

If it becomes apparent during our examination of damage reported by the customer or in the course

of repairing defects that the reported damage or claims were made wantonly or were unwarranted,

we may charge for inspecting and repairing defects. The customer has the right to reject a necessary

repair and to demand the return of the pump. In general, every inspection of damage is bound to lump sum compensation

if it appears that the customer is responsible for the damage.

WARNING – ELECTRICAL HAZARD! DANGER OF DEATH!

WARNING – ELECTRICAL HAZARD! DANGER OF DEATH!

Only appropriately trained personnel may commission and maintain Synchronous Compact Drives.

These personnel must be familiar with international accident prevention regulations.

Connection and setup must be carried out in compliance with the electricity regulations.

The manufacturer is not liable in any way for any damage caused by improper installation or by the carelessness of the user or installer.

3.3. Use of the pump - Symbols used Symbols used

Never use the pump with any other liquids than water.

Attention:

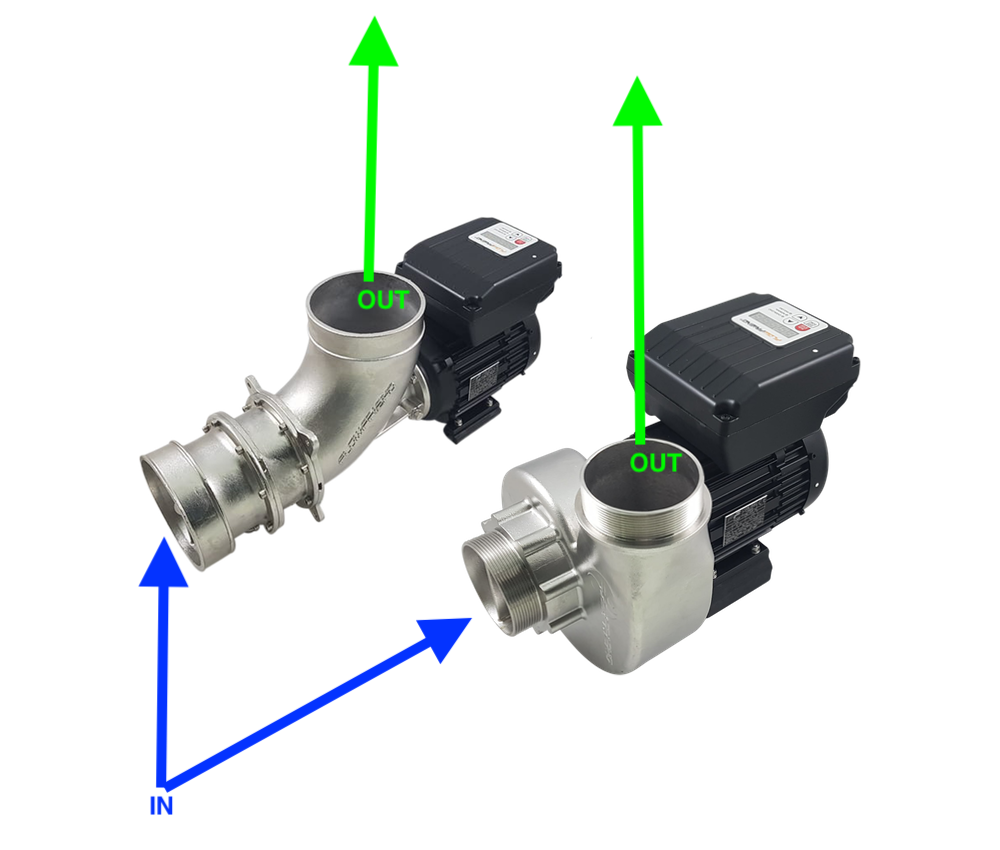

The pump may only be used in a horizontal position. It must stand on a stable, solid base. The inlet pipe is connected to the suction side of the pump.

The FlowFriend has a protection class IP55.

If a sufficient amount of water does not reach the pump because the drag of the inlet pipe is too strong, the pump will use a lot of power and the electronics might become overheated in the long run.

6.3 Pressure pipe (Pump outlet/pressure side)

The pressure pipe must have the same diameter (3"/90 mm) as the intake of the pump in order to minimize pressure loss, high flow speeds and noise.

The best thing is if you enlarge the pressure pipe directly after the pump outlet if the outlet piping exceeds 10 meter, in order to maximize the pump capacity and to safe energy.

6.4 Electrical connection – setting-up operation

Check whether voltage and frequency on the type label of the pump match the supply voltage. The person responsible for the installation must check whether standard grounding is available.

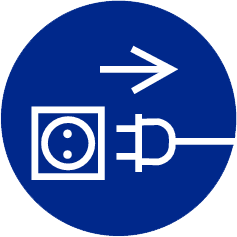

Disconnect the pump from the power supply prior to any maintenance work.

7.1 Disassembling/turning the pump housing

Please note: The following instructions for dismantling and turning the pump head only apply to the Standard type.

For the type Flowfriend Pro we advise you to have this work carried out by a specialist.

7.2 Decalcification and cleaning of the impeller

Please decalcify the impeller using appropriated calcification baths.

Never use hydrochloric acid, not even if diluted! This may damage the pump. Suitable media are: formic acetic phosphoric acid or common decalcifying agents

for water purification appliances such as coffee makers.

The FlowFriend is equipped with a membrane keyboard and a digital display with five 7-segment digits.

Use this key to change the operation mode. While the motor is running, the display shows the current speed. When the motor is switched off, the display shows “0”.

These keys are for changing the set point speed. Once one of the keys is pressed, the speed can be adjusted. Note that the value can be increased or decreased

in steps of 10 rpm from a minimum of 600 rpm to a maximum of 2550 rpm. While pressing the key permanently, the value changes more quickly.

8.3 Showing the current power consumption

In normal mode, the display shows the set point speed. After pressing the DISP/FUNC key, the display will show the current power consumption in Watts (± 10%), prefixed by a 'P' for Power.

By pressing the key again, the operating hours are shown, prefixed by the letter ́h ́ and the display shows the counter value alternately.

The operations hour counter will overflow when exceeding 99.999 hrs. (11½ years).

By pressing the key DISP/FUNC again, the display shows “Id“ on the left and software version on the right, i.e. “100“ for software version 1.00.

The display shows “t“ on the left and power module temperature in °C on the right.

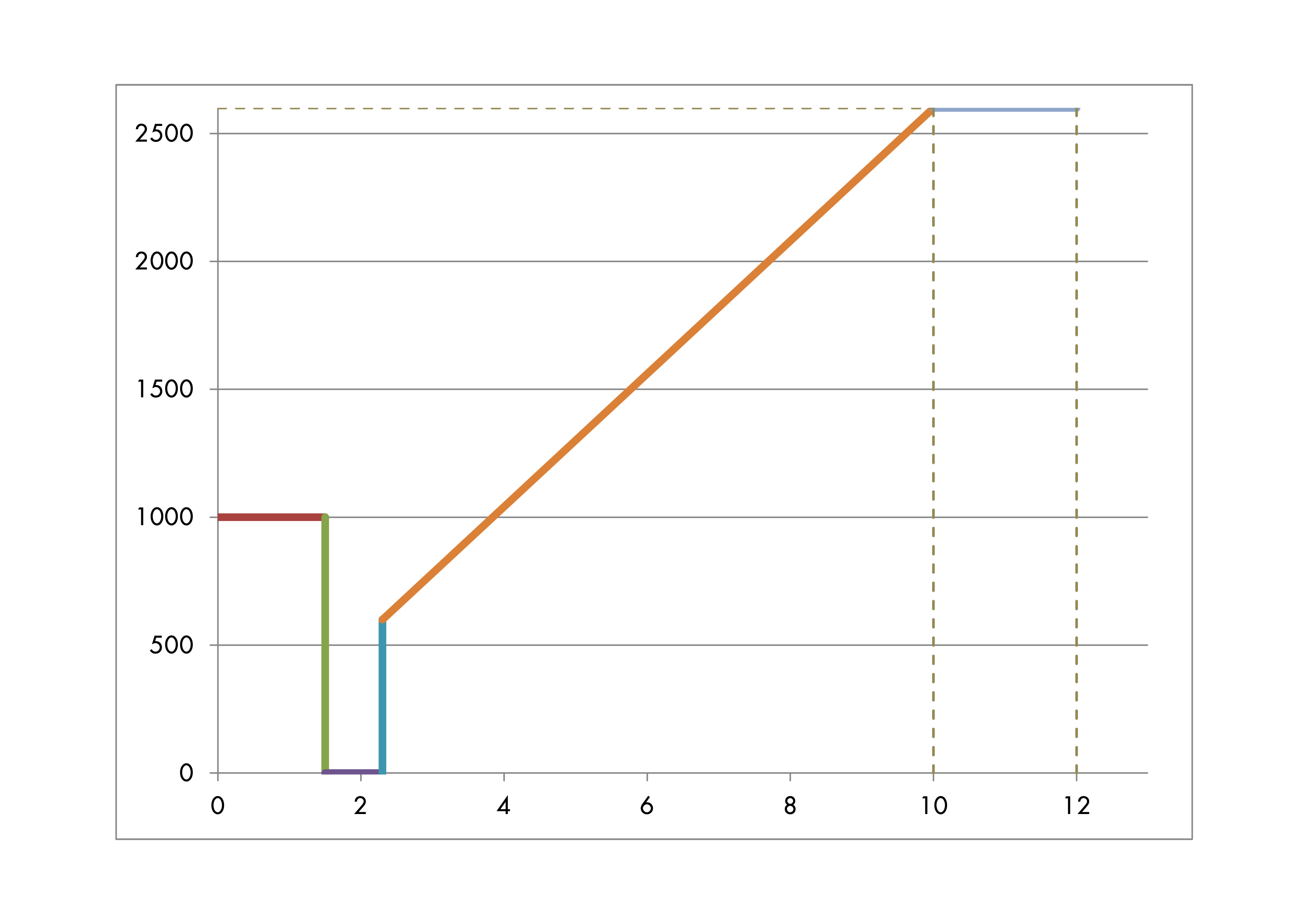

The FlowFriend can optionally be equipped with a 0-10V drive.

This set-up is either built-in by Air-Aqua or by an electrical engineer in consultation with Air-Aqua.

With this drive, the pump can be controlled externally according to the diagram below, where the ratio between the supplied voltage (horizontal axis) and the speed (vertical axis) is indicated.

Attention: The voltage is not allowed to exceed 12V, then the device is damaged.

The FlowFriend is protected against overload and overheating.

To protect the power module from overheating, the junction temperature should not exceed 150°C. When reaching 105°C, the motor will slightly reduce the output power.

In the case of overheating, the motor will stop showing “Oload” and restart when the temperature is below 95°C. The LED “Overload“ is blinking.

Try to identify the reason for overheating and remedy it, i.e. by cleaning the fan cover and SCD surface. After pressing the RUN/STOP key, the drive is stopped and the drive

can be started manually by pressing the RUN/STOP key again.

If the motor stalls, the controller will try to restart the drive 5 times within 2 minutes. The display will show the message “RSTRT”.

After failing to restart the pump, the display will show an error message “Er20“. After acknowledging the error by pressing RUN/STOP key,

the motor will start again. The counter is reset during the next start procedure.

During normal operation mode, the electronic controls the motor. If there is no response from the power module electronic, the control unit will stop the motor and show “Er98“ communication error.

The LED “Failure“ is blinking.

10.4 Internal electrical failures

In the case of an internal failure caused by a defect component or short-circuit, the drive will stop running and display the occurred failure.

If the advice is to restart the engine again (see table below):

Power:

Titles against Air-Aqua BV concerning the

products described in this manual address the Air-Aqua BV guarantee clauses and General Terms and Conditions.

If you need more help, please contact your dealer. It is useful to have all the data of your system at hand, such as piping, UV, etc.

REMOVE PLUGS

REMOVE PLUGS

Remove the plug from the electric socket and make sure that the pump cannot be switched on. During the course of the installation, the pump may not be connected to the power supply.

CAUTION!

CAUTION!

Before connecting the device, make sure there is no damage. Check the power cable mains plug carefully before connecting.

After plugging in the power cable for the first time, the motor is waiting for input of the desired speed. Please note, the motor will set and store the start up speed automatically after

4 seconds of manually setting the speed. After connecting to the power mains, the motor performs a self-test for about 3 seconds.

WARNING – ELECTRICAL HAZARD! DANGER OF DEATH!

WARNING – ELECTRICAL HAZARD! DANGER OF DEATH!

Electrical shocks can cause death or serious physical injury to personnel as well as pose a risk to equipment. Ensure that no unauthorised

persons are able to gain access to or come into contact with the device. Disconnect the device from the power supply before opening the device

or the terminal box. Due to DC link capacitors, hazardous high voltage may remain for up to 3 minutes after disconnecting from the power supply.

Never operate the device when the mains is not properly connected to earth.

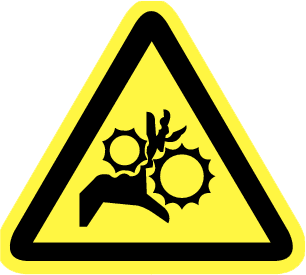

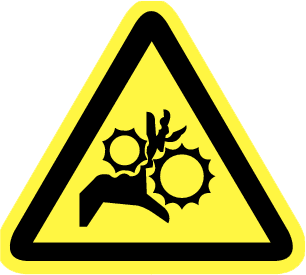

CAUTION! ROTATING PARTS! AUTOMATIC RESTART!

CAUTION! ROTATING PARTS! AUTOMATIC RESTART!

Please take every precaution to ensure

that all rotating parts, including the internal fan, are safe from contact while the motor is running. Operating the device with automatic restart can be a source of danger to operating personnel. After power failure, the motor will only start automatically

if it was running when the power failure occurred.

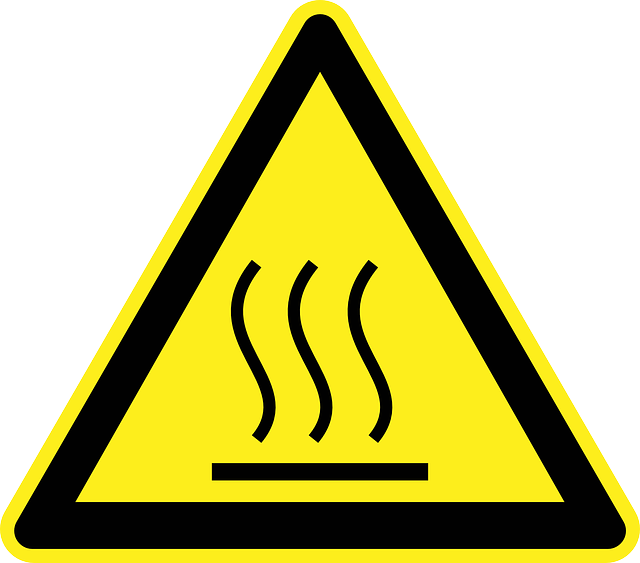

WARNING! HOT SURFACES! RISK OF INJURY! RISK OF FIRE!

WARNING! HOT SURFACES! RISK OF INJURY! RISK OF FIRE!

Heated surfaces can cause serious physical injury to personnel or ignite material in the near vicinity.

In general, when put out of service, the pump must

be cleaned extremely thoroughly. The pump must be stored in a dry, warm place to prevent condensation/ moisture getting into the electronics which could cause damage when used again.

Before it is put into operation, the ease-of-movement of the impeller must be manually checked. If the impeller cannot be moved round by hand, the pump must be disassembled and cleaned completely.

The plug may not be disconnected from the mains whilst the device is in use. This can result in serious damage to the electronic components and cause dangerous situations due to grounding problems.

Before you get the plug from the socket, you must first stop the pump with the RUN/STOP key.

The wiring may not be modified or replaced. Electrical installations on garden ponds must always comply with national and international directives and requirements. Never open the case of the device or of the appending parts.

Never apply technical modifications of the device.

Only use original spare parts and accessories. Only allow authorised customer service facilities to conduct repairs.

The FlowFriend pump is suitable for freshwater and brackish water. The FlowFriend can pump clean as well as – to a certain extent – polluted water. The pump is not suitable for water with larger particles. The pollutants may not exceed 10 mm in size. In general the pump should be used for applications with clean water. Clean water in this case is defined

as water not containing solid particles, which could damage the impellor/bearings and/carbon ring/pump housing.

Examples of particles or pollutants which are not suitable are sand, lime precipitation or pyrolusite after a manganese peroxide treatment in a pond.

Damage caused by such pollutants in the water does not fall under warranty or service.

FlowFriend pumps are most commonly used in filtration systems (aquariums, ponds or swimming pools), industrial circulating systems and/or to supply a beck/ creek or waterfall.

The pump is not self-priming and may not therefore be used above the water surface.

Technical information:

Temperature of the water: 2 to 40°C.

Environment temperature: 0-50°C

Max. static pressure:

PRO: 0.28 bar

Standard: 0.72 bar

Protection class: IP55

Before you install the pump, read the manual carefully. Damage caused because the manual was not read thoroughly does not fall under warranty.

When unpacking the pump, check whether all parts have been delivered completely and undamaged. Any damage detected must be reported to your retailer within 24 hours of purchasing the pump.

Please check the pump for damage before you operate it. Do not use the pump if it is damaged. Please inform your retailer immediately if the pump is used despite being damaged.

Any warranty and liability will then be invalid.

Remove the plug from the electric socket and make sure that the pump cannot be switched on. During the course of the installation, the pump may not be connected to the power supply.

To avoid injury, take care not to reach into the opening of the pump with your hands or fingers when the pump is connected to the power supply.

THE PUMP CAN AUTOMATICALLY START WHEN THE POWER CONNECTION IS ESTABLISHED.

It must be assured that the pump can be de-aerated through the outlet. The pump should ideally be placed below water level.

The pump can be only placed out of the water (dry). Adequate air ventilation must be assured.

Furthermore the pump may not be exposed to direct sunlight. Place the pump as close as possible to the actual water connection. The inlet piping must therefore be as short as possible.

IP55 water protection does not mean that the pump can be mounted outside unprotected from rain. The IP55 is a specific test involving specific spraying of the pump for a specific time.

Remember that electronics and water are enemies. Provide good protection from rain if mounted outside. Damage caused by water is not covered by warranty.

Siting is preferably at a minimum of 10 cm above ground level. This will prevent the pump being 'drowned' if a connection becomes loose and water spills on the floor.

We strongly recommend placing the pump below water level. If the pump is placed above water level, the installation of a back pressure valve is mandatory.

In this case, the inlet piping of the pump must be filled with water before the pump is operated. In such a setup, the risk of the pump running dry is very high,

if the back pressure valve does not work properly. Damage caused by the pump running dry is excluded from warranty.

Any coupling must be 100% air-proof. If a tube is used as inlet, this must fulfil the requirements of a suction pipe.

It is very important that the initial inlet at the pump is straight. (Minimum distance of 3-5x the diameter

of the inlet pipe from the housing to the first bow). This maximises the efficiency factor because the water enters more laminary at the impeller.

If the inlet piping is longer than max. Ø x 10, the inlet piping must be 1 size larger than the intake of the pump.

Reducing of the diameter of the pump outlet is at the FlowFriend pump to avoid.

It must be checked whether the electrical installation has a highly sensitive earth leakage circuit breaker (ELCB/GFCI) (30mA – DIN VDE 0100T739).

FlowFriend pumps are generally low maintenance. All in all, FlowFriend pumps only need to be inspected for calcification and deposits in the stator space and the

impeller at regular intervals and cleaned or decalcified if required.

Remove obstacles from the impeller with a slender, pointed tool. A decreasing supply rate is often the result of dirt.

Possible calcinations must be removed with a very soft acid like vinegar. Avoid applying pressure to the sides of the impeller or the rotor.

The pump housing can be disassembled completely for cleaning.

The PRO pump housing may only be dismantled by a specialist. For cleaning the pump head, the PRO is also very easily accessible without dismantling.

Calcification is generally a problem when the ponds are topped up with tap water at an initial water hardness of over 10 dh.

When initially/refilling ponds with tap water with a high lime content, sudden lime precipitation may occur within 2-3 days.

Unplug or disconnect the power plug and gently remove the pump from the system. Remove the 8 bolts on the back of the pump housing.

Then gently remove the pump housing itself. Check the impeller for snail shells, mussels, active carbon pellets, filter cotton or residual food. In the case of larger accumulations, please clean the impeller.

Pump damage caused by blockages or forceful disassembly is not covered by warranty services.

Coarse, greasy plaques must be removed under ordinary tap water prior to decalcifying using a medium-coarse brush.

Please observe the relevant safety regulations attached to every sales package prior to using decalcifying acids. Wear protective clothing and goggles.

Regular maintenance guarantees a long running time and service life.

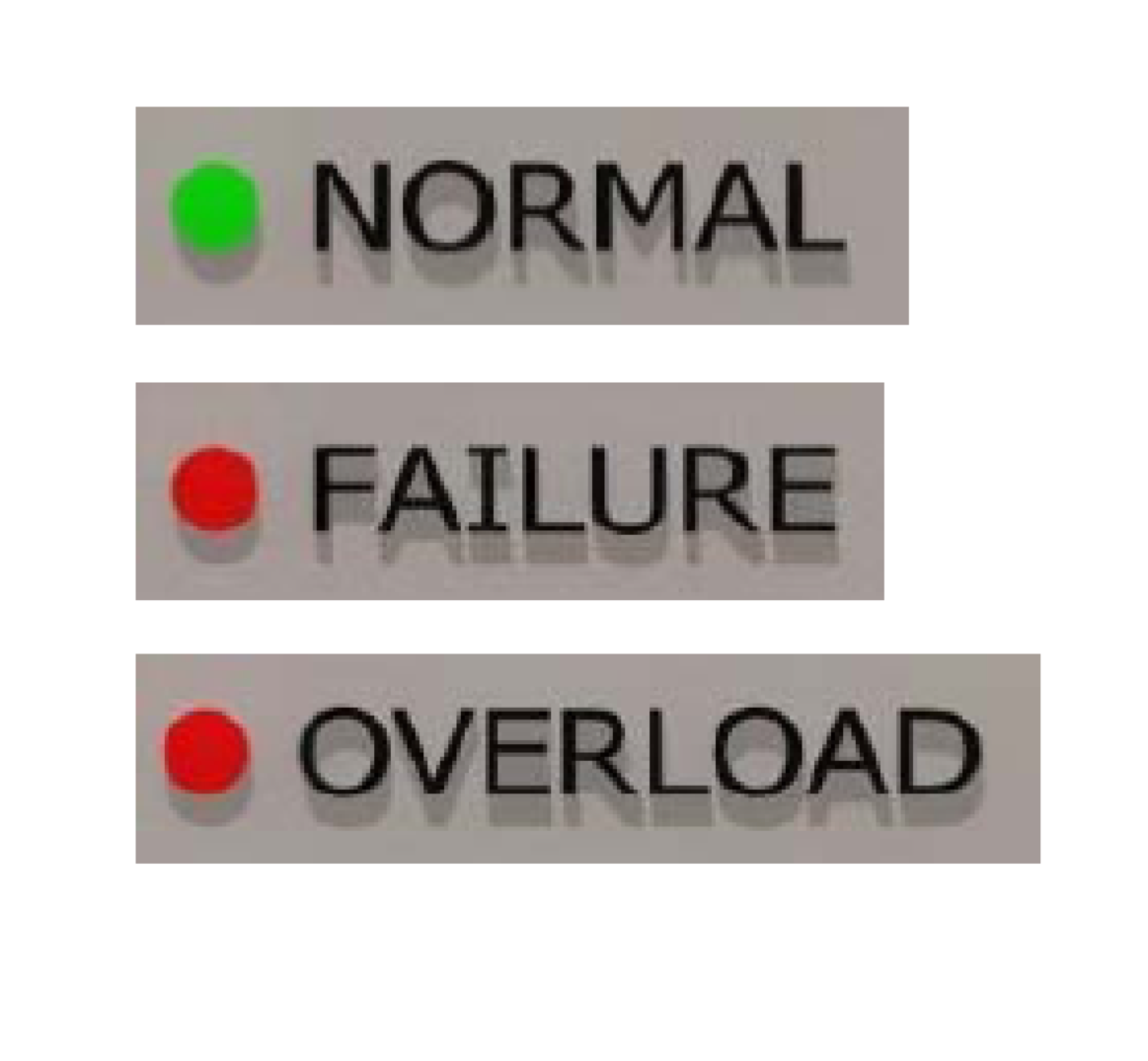

The LED indicators show the following:

Normal = Normal operation

Failure = Motor failure is detected

Overload = Motor is overloaded during operation

If 'Normal' and 'Failure' burns at the same time, the situation is like that of 'normal operation' and no further action has to be taken. The pump functions normally.

To connect the cables to the external 0-10V source:

Warning:

Be careful: the surface of the electronic control box may be hot. Do not touch the box directly before verifying the surface temperature.

The pump must first be checked for water damage. In the event of a short circuit and renewed switching on the pump, this leads to irreparable damage to the electronics.

With water damage, the pump must be immediately dismantled and dried to limit damage as much as possible.

After pressing the RUN/STOP key, the error message is deleted and the pump can be restarted by pressing the RUN/STOP button again.

Error code

Description

Action

1

Under voltage

Failure LED on, Try to Restart drive

2

Overvoltage

Failure LED on, Try to Restart drive

3

Under voltage during start

Failure LED on, Try to Restart drive

4

Maximum temperature exceeded power module

Overload LED on, speed will automatically be reduced

5

Overtemperature motor

Overload LED on, Try to Restart drive

7

Maximum current exceed

Overload LED on, Try to Restart drive

10

Current measurement fails permanently

Failure LED on

20

Overload during start up process

Overload LED on, Try to Restart drive

64

Short circuit failure

Failure LED on, Check for water damage -> contact Air-Aqua

97

Multiple errors

Failure LED on, Check for water damage -> contact Air-Aqua

98

Communication failure from controller

Failure LED on, Try to Restart drive

FF PRO: 20-750Watt

FF Standard: 20-750Watt

Voltage: 100-240VAC

Max. current: 4.4 A

Frequency: 50-60 Hz

Isolation class: F

Protection class: IP55

Max. rpm: 2550

Motor torque: 2.4 Nm (from 800 rpm)

Motor efficiency: IE4 88-94% (600-2550 rpm)

Capacity:

FF PRO: 15-105 m3/hr

FF Standard: 5-70 m3/hr

Pump head:

FF PRO: 0-2.8 meter

FF Standard: 0-7.2 meter

Hydraulic efficiency: 36-82%

IE4 A++

Mechanical Seal: Eagle Burgmann MG1Q1Q1VGG

Connection Suction:

FlowFriend PRO - 125 mm

FlowFriend Standard G 3“ x 20 mm - outer thread

Connection Pressure:

FlowFriend PRO - 125mm

FlowFriend Standard G 3“ x 20 mm - outer thread

Dimensions:

Link to dimensions FlowFriend PRO

Link to dimensions FlowFriend Standard

FlowFriend Flowchart:

Link to Flowchart FlowFriend PRO

Link to Flowchart FlowFriend Standard

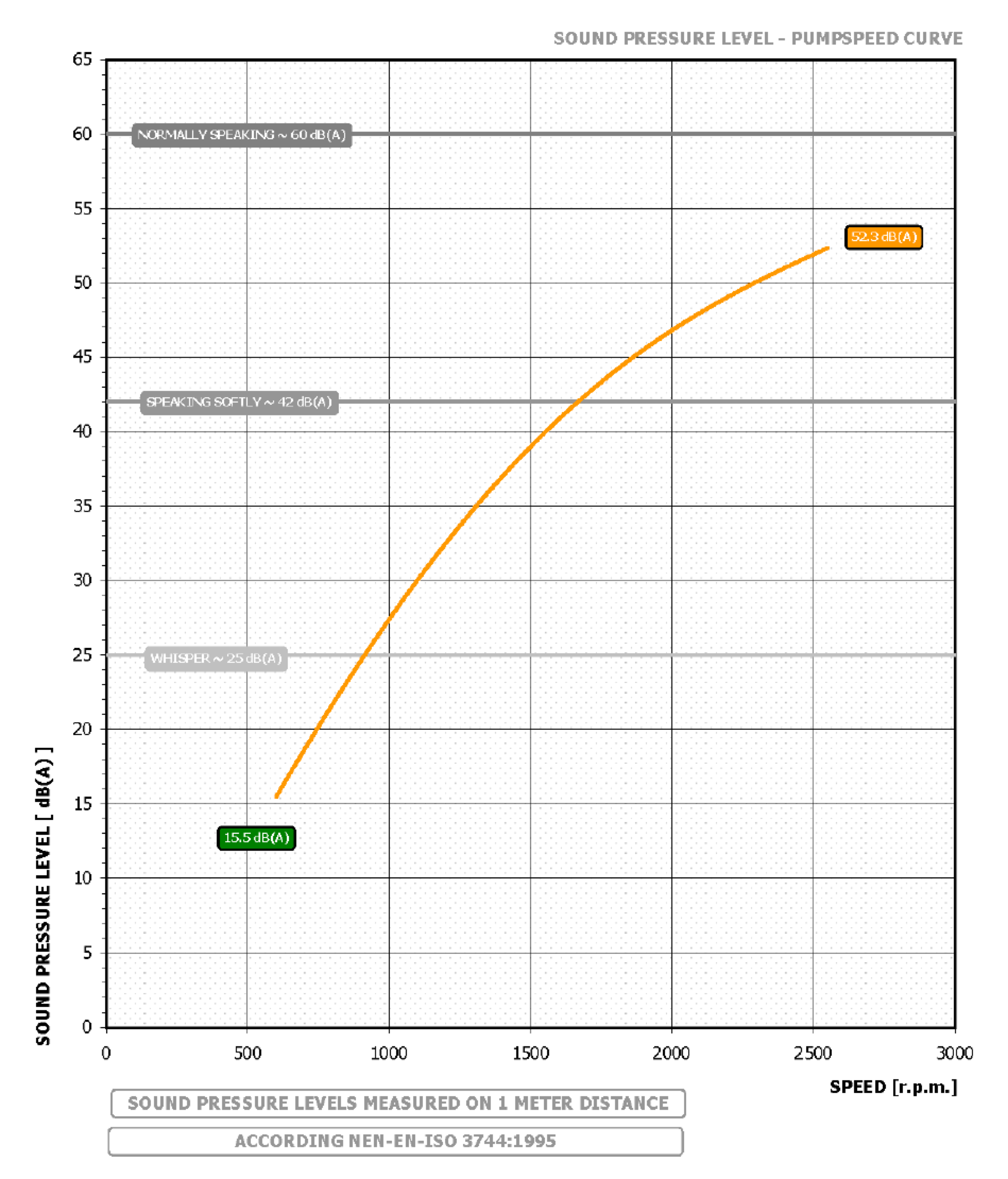

Noise Data:

Specifications may vary due technical improvements/changes.

If the device fails to meet the high demands you expect from Air-Aqua BV, please contact the dealer from whom you purchased your FlowFriend pump.

This is usually the best way for product support. However you may feel free to contact us.

AIf you have any questions or problems, consult an electrician, your dealer or Air-Aqua BV.

Distributor:

Air-Aqua BV

FlowFriend pumps are subject to new developments and technical changes. The information and images in this manual are intended as a guideline.